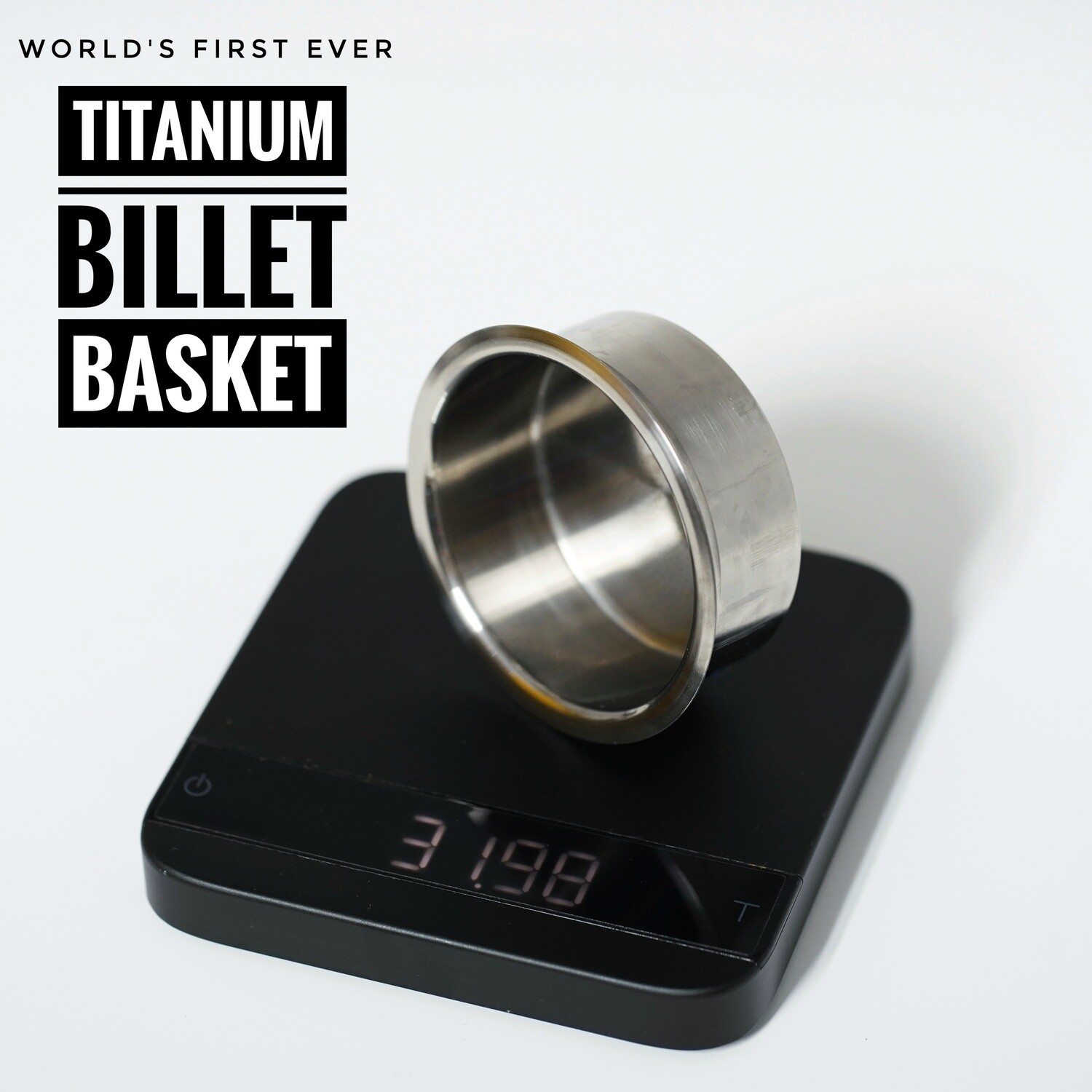

Titanium Billet Basket

WORLD'S FIRST Titanium Espresso Basket!!!

Who else would be crazy enough to make a billet titanium basket!? After making the highest strength baskets from hardened 17-4 stainless steel, I turned to titanium for the next challenge. This high strength/lightweight titanium is typically used for implants, aerospace structure and engine components to name a few.

I've written before that the raw material alone to produce a Billet Basket cost more than a high end stamped basket. Well the raw titanium material cost is almost the same as a Billet Basket… Unlike the 17-4 counterpart, titanium did not react well to laser cutting (holes) so each hole was painstakingly drilled - a 12 hour operation for just the holes on this Standard Flow pattern. Don't even ask about the High Flow pattern…

The end result is a 30% lighter basket (or the same weight as a thin stamped basket) but still strong enough to NOT deform permanently under 9 bars of pressure. No sacrifices were made to the hole coverage in order to achieve the same strength.

Why would you want this? You shouldn't want it unless you are a bit crazy about this stuff like I am! Recently made a small batch by customer request and have two left over.

Visit the Billet Basket page for specs on hole count, dimensions, etc.

Quick Notes:

- This is a 58mm, 18-20g, Standard Flow version

- Non-magnetic

- Holes are individually drilled, not laser cut

- Engineered to withstand 9 bars of pressure without permanent deformation or sacrifice in hole coverage compared to my Billet Basket

- Same weight as a thin stamped basket or 30% lighter than my Billet Basket